Innovative Design in Action - The Reflux and Inerting Manifold from Amigo Chem

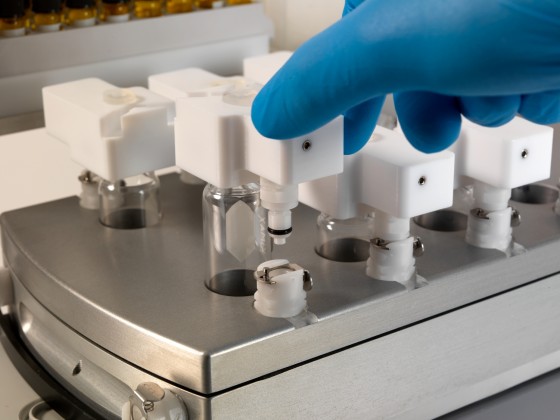

Amigo Chem recognized that the compact Integrity 10™ reactor block requires serious consideration to ensure that the 10 reactor vessels can be added and removed with ease and that gas and coolant feeds to these vessels do not interfere with reactor vessel handling.

Extensive user survey and discussion has provided Amigo Chem with a user requirement that led to the novel Amigo reflux and inerting manifold. It is with great pleasure that we learn that our design has been widely accepted and applauded by all those that have used it.

Excellent Reflux Performance

The customer data shown in the table demonstrates minimal levels of solvent loss during 16 hours of reflux at least 10 °C above boiling point. The manifold was connected to a coolant feed at 15 °C.

| Solvent | Boiling point (°C) | Reactor temperature (°C) | Nitrogen flow | weight loss (%) |

|---|---|---|---|---|

| THF | 66 | 76 | Yes | 2.5 |

| THF | 66 | 76 | No | 2.8 |

| Acetonitrile | 82 | 95 | Yes | 1.4 |

| Acetonitrile | 82 | 95 | No | 0.6 |

| Methanol | 65 | 80 | Yes | 2.5 |

| Methanol | 65 | 75 | No | 0.7 |

Flexible Operation

- Step 1: Use the quick connectors at the front and rear to hook up coolant and inert gas feeds. This configuration provides a static inert headspace. If a flowing inert gas supply is required to remove gaseous product, simply attach the Amigo bubbler to the gas exit.

- Step 2: Charge the reactor tube with reactants and screw into the PTFE cap.

- Step 3: If an inert headspace is required, snap the vessel into the Amigo pump and fill station. Manually switch the valve to select vacuum and gas. Press the release button. The reactor cap check valve retains the inert headspace. (The video has no sound.)

-

Step 4:

Simply push down the reactor tube into a vacant position in the Integrity 10™ block. Note: the Amigo Workstation allows the user to plug in reactors any time to a running method safely.

-

Step 5:

The manifold quick release button allows for reactor removal from the running system for visual checks or for off-line work up, etc.